Mintech Cnc Beam Saw MS2600 Machine

-

Total Weight :5000KG

-

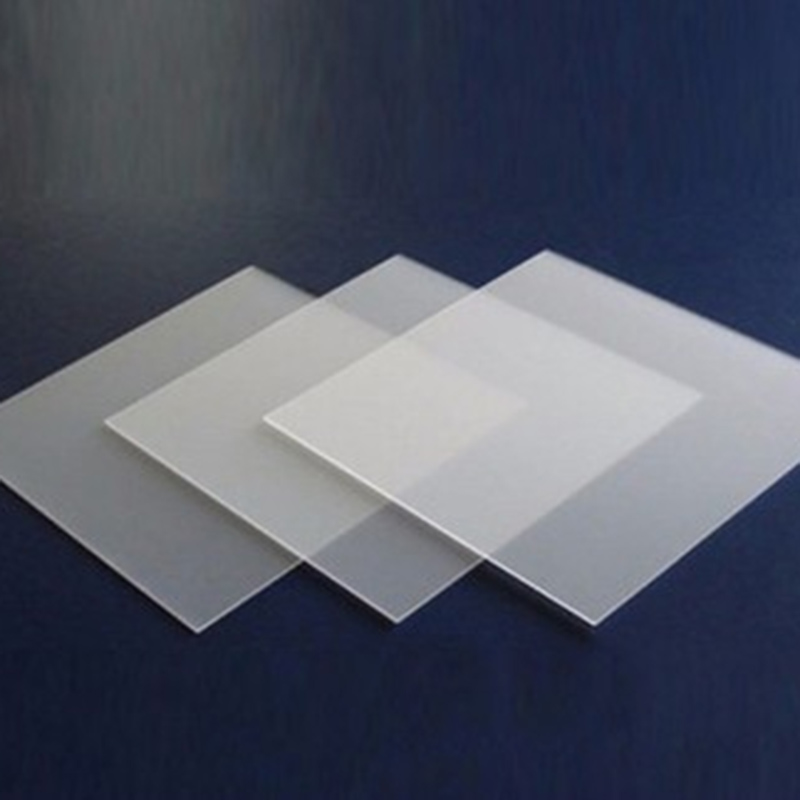

Working Size :2500X2500MM

-

Machine Size:5500×5600×1700MM

List Of Machine Configurations

|

Model |

MS2600 |

|||

|

Total Weight |

5000KG |

|||

|

Working Size |

2500X2500MM |

|||

|

Machine Size |

5500×5600×1700MM |

|||

|

Working pressure |

≥6KG/CM2 |

|||

|

Working Voltage |

AC380V 50Hz(Three-phase four-wire ) |

|||

|

Main Spindle Speed |

7.5KW/11KW |

|||

|

Scoring Spindle Speed |

1.5KW |

|||

|

Feeding Saw Voltage |

1.5KW |

|||

|

Cutting Saw Voltage |

1.5KW |

|||

|

Working Thickness |

≤80mm(according to the material) |

|||

|

Effective Processing Length |

2500MM |

|||

|

Effective Processing Depth |

2500MM |

|||

|

Cutting Speed |

20-80m/min(Step-less speed regulation) |

|||

|

Straight Line Cutting Accuracy |

0.2mm/2500mm |

|||

|

Feeding Accuracy |

±0.15MM |

|||

|

Diagonal Accuracy |

1200/2400<0.5MM |

|||

|

Feeding Speed |

30m/min |

|||

|

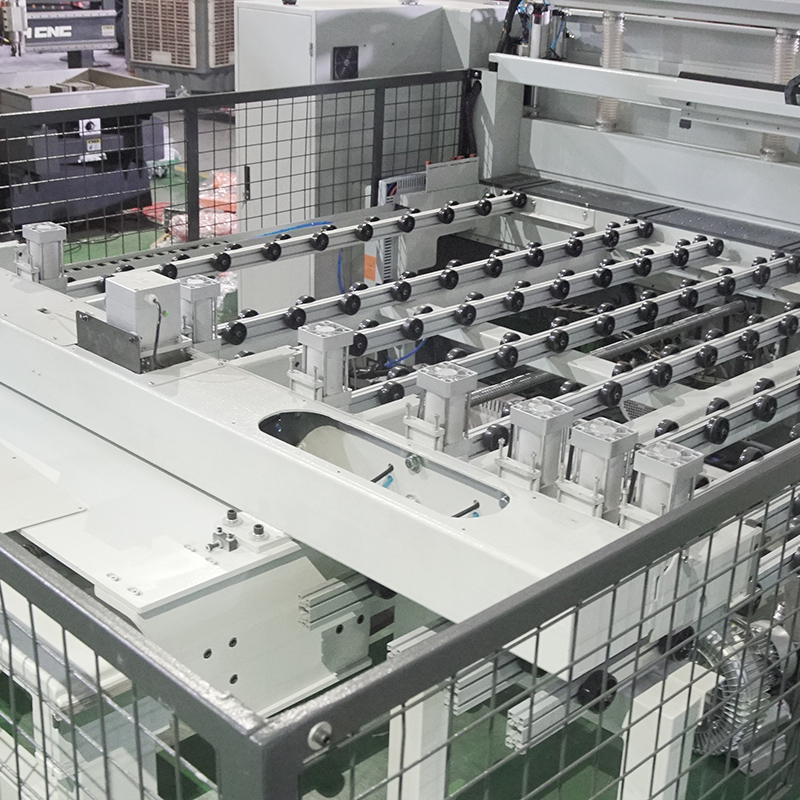

Feeding & Cutting Drive Mode |

Gear rack |

|||

|

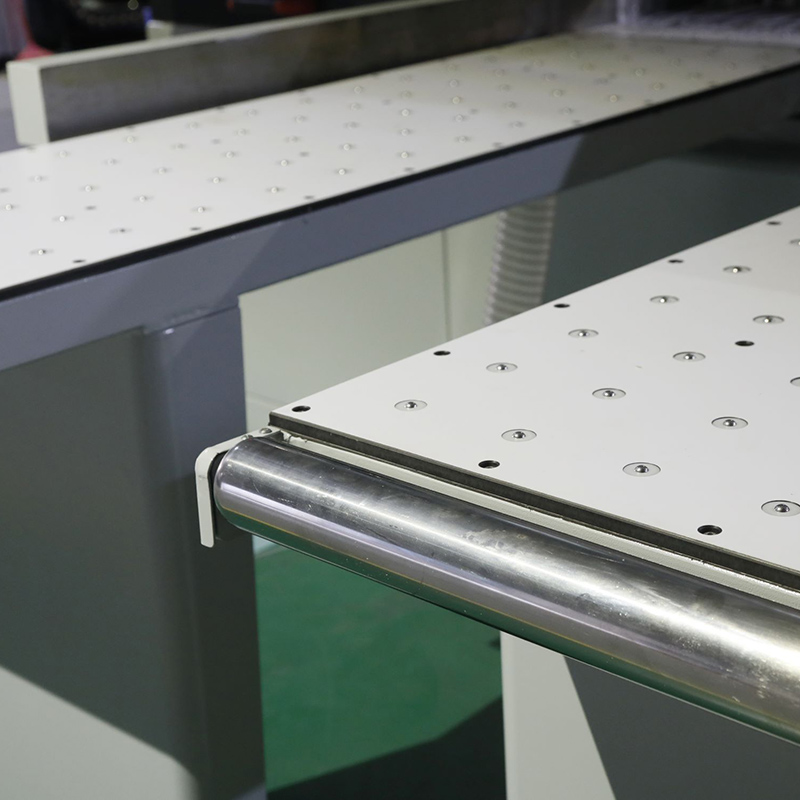

Feeding Structure |

Pneumatic float |

|||

|

High Pressure Fan Power |

2.2KW |

|||

|

Targeting |

Pulse servo position control |

|||

|

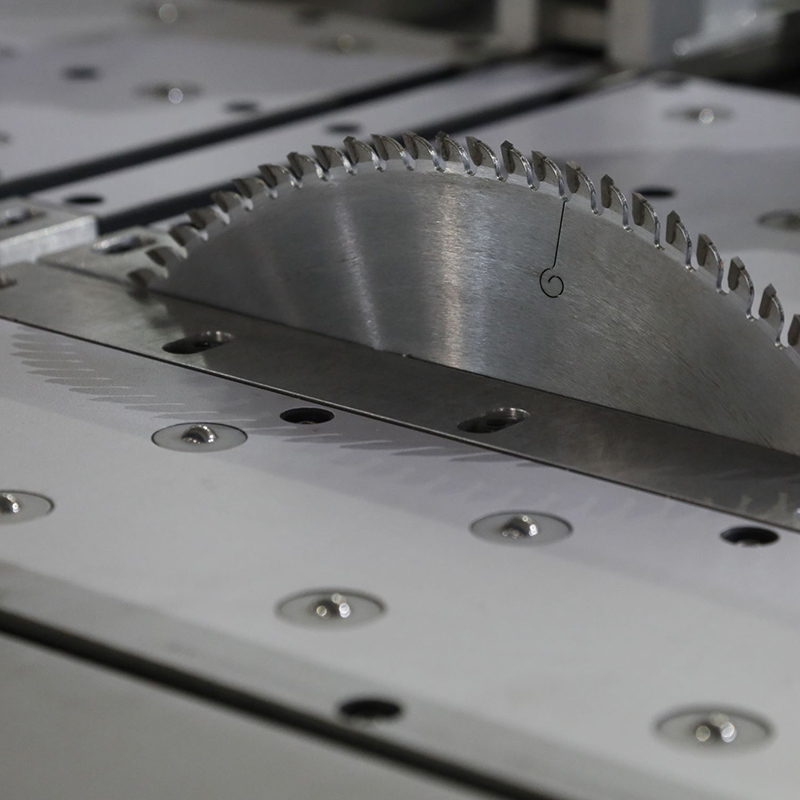

Main Saw Specifications |

Outer Diameter |

φ305MM-φ355 MM |

||

|

Inside Diameter |

Φ30MM |

|||

|

Thickness |

3MM |

|||

|

Slot Saw Specifications |

Outer Diameter |

φ180MM |

||

|

Inside Diameter |

Φ30MM |

|||

|

Thickness |

2.9MM-4 MM |

|||

|

Main Saw Speed |

3950~4500 rpm(Variable Frequency Conversion) |

Slot Saw Speed |

5400 rpm |

|

|

Total Power |

17/21 KW |

|||

Product Introduction