01

Mintech MYD-1360 Acrylic double side polishing machine

-

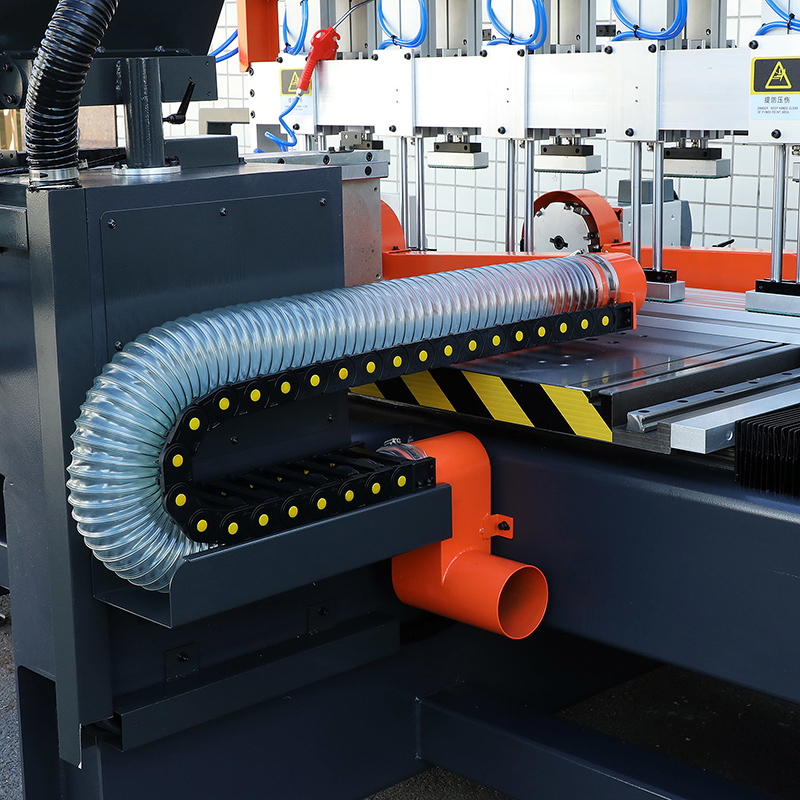

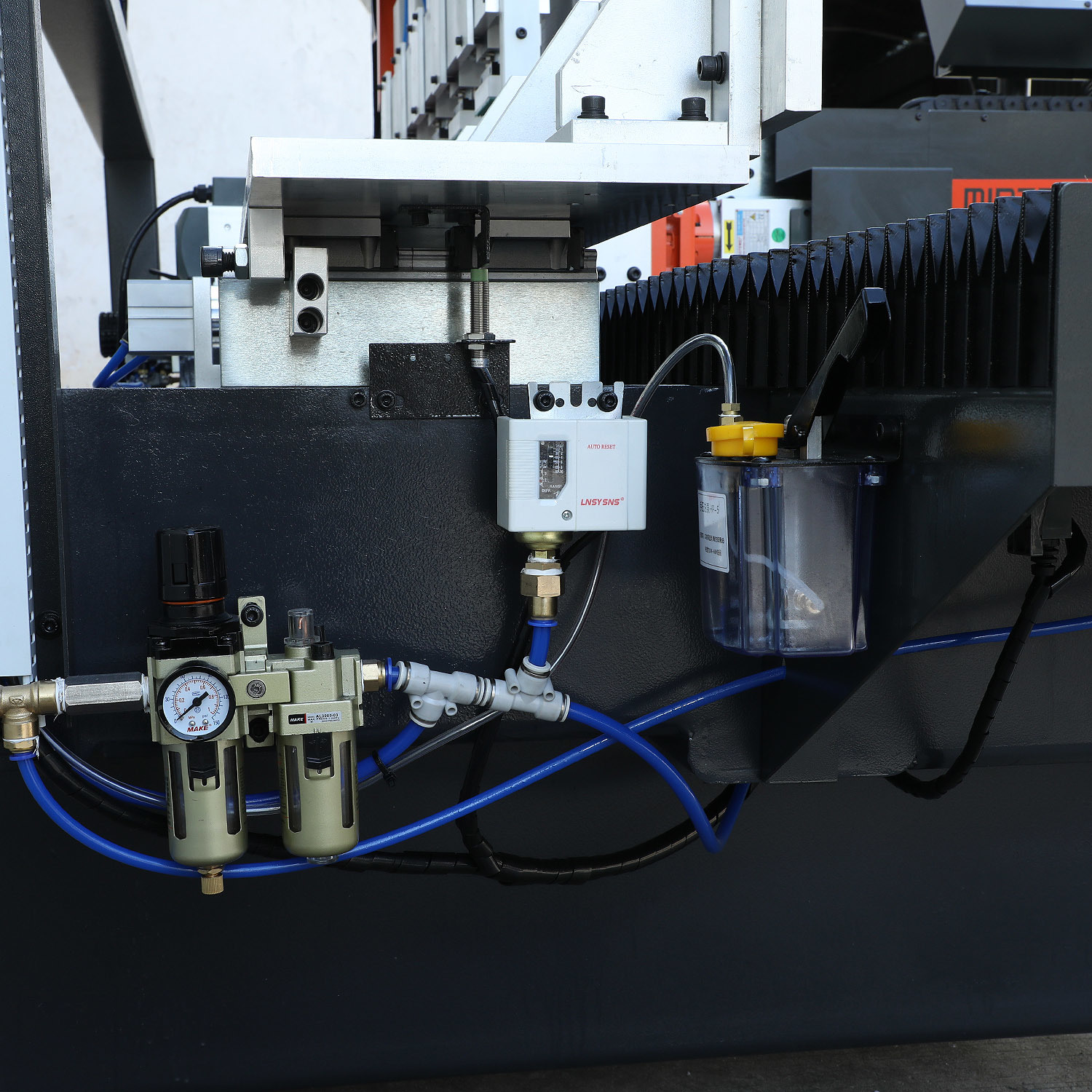

We maintain linear processing accuracy within +/- 0.1mm over a span of 1600mm. This machine utilizes servo drives and high-precision ball screws and square guide rails to ensure accurate processing results. The control system is equipped with a PLC digital control system and features a user-friendly touch screen interface for straightforward operation. With a spindle motor power of 2.2KW and a top speed of 9000RPM, and air cooling to effectively protect the motor, our polisher is built for efficiency.

MYD-1360 Acrylic High Speed Polishing Machine

|

Model |

MYD-1360 |

|

Working voltage |

AC380V / 50HZ / 3PH |

|

Working size |

1300mm×60-600mm×100mm |

|

Min polishing width |

60mm |

|

Max working speed |

2m/min(adjust by tool and material) |

|

Max idle speed |

4m/min |

|

Linear machining accuracy |

+ / - 0.1mm(within 1600mm) |

|

Driving mode |

Servo drive,adopt high precision ball screw and gear transmission |

List

| Con | Spec. |

No |

Remark |

| Dimension | 3500mm×2300mm×1470mm |

|

|

| Working size | Thick100mm、length1300mm、width 60-600mm |

|

Min width 60mm |

| Linear machining accuracy | ±0.08mm |

|

1300mm |

| Machining vertical accuracy | ±0.08mm |

|

100mm |

| Working speed | 0-2000mm/min |

|

adjustable |

| Idle speed | 4000mm/min |

|

|

| Processing tool amount | 0-2mm |

|

adjustable |

| Spindle motor | 2.2KW |

2 |

|

| Feeding motor | Material feeding motor 1KW Cutter head feeding motor 500W |

1 |

Servo from Delta, Taiwan |

| Bevel polishing | 0° |

|

|

| Inverter | Invt |

2 |

|

| Feed amount control | Servor touch panel control system |

1 |

|

| PLC controller |

1 |

||

| Touch panel |

1 |

||

| Main power | 4.5KW |

|

|

| Total weight | 2800Kg |

|

|

| Cutter head | Three-blade |

|

Six-blade optional |

| Rough tool | PCD(MY01) |

4 |

Two pieces for each cutter head |

| Fine tool | PCD(MY02) |

2 |

one pieces for each cutter head |

| Tool box |

1 |

||

| Dust collector | 2.2KW |

|

optional |

| Diamond polishing tool | single crystal |

|

optional |

01

Control system & human-machine interface

7 Jan 2019

PLC control system

Touch HMI

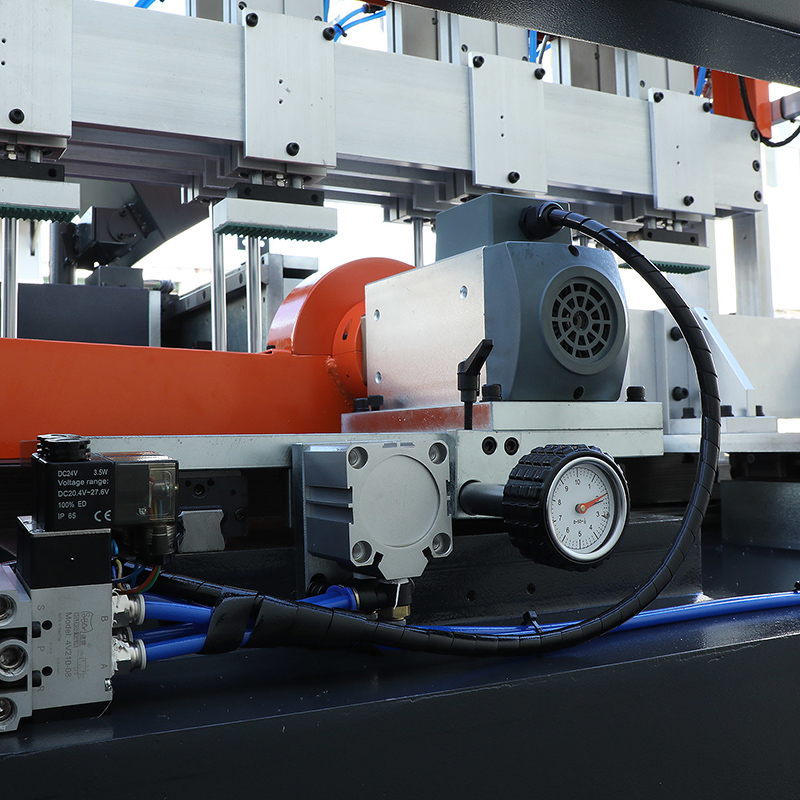

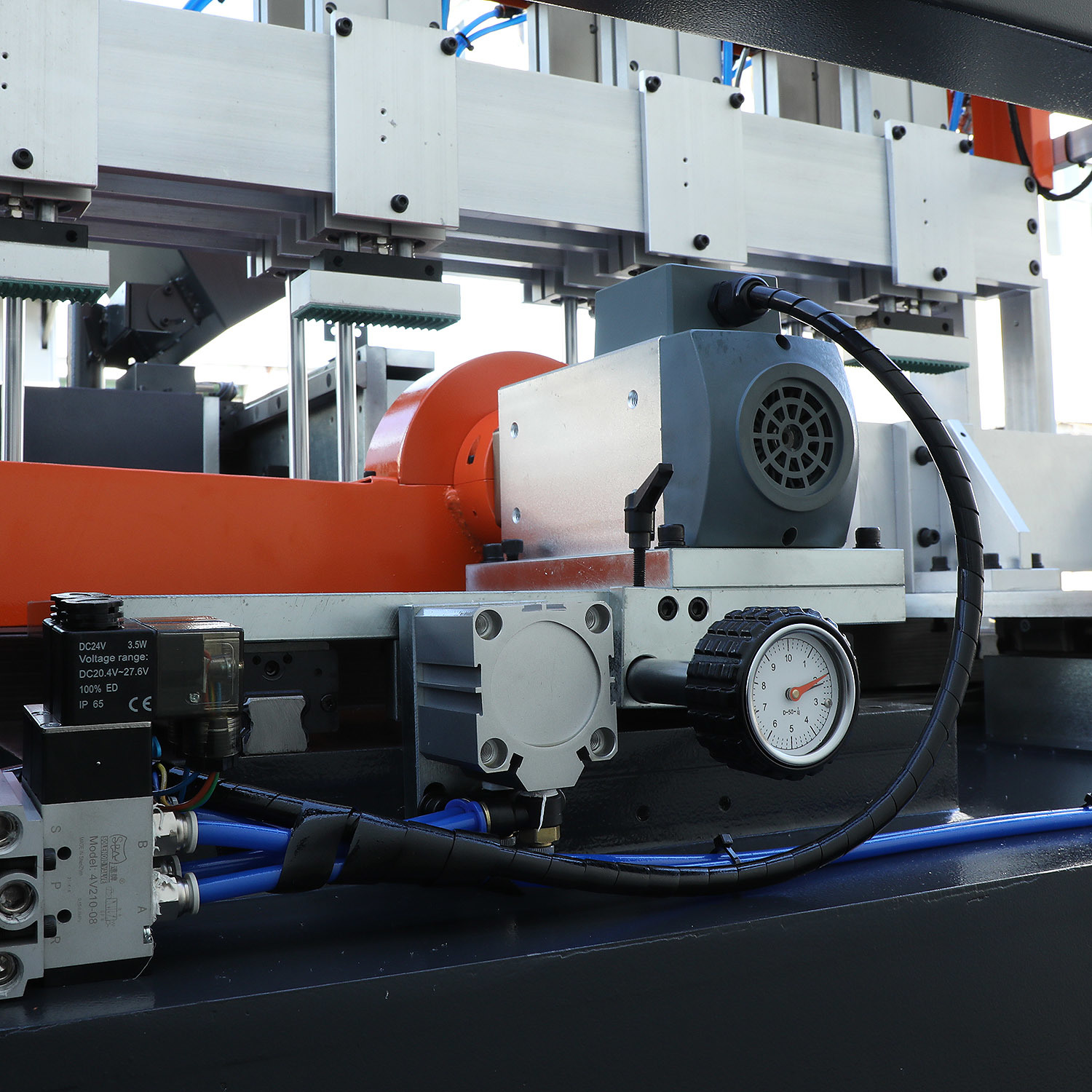

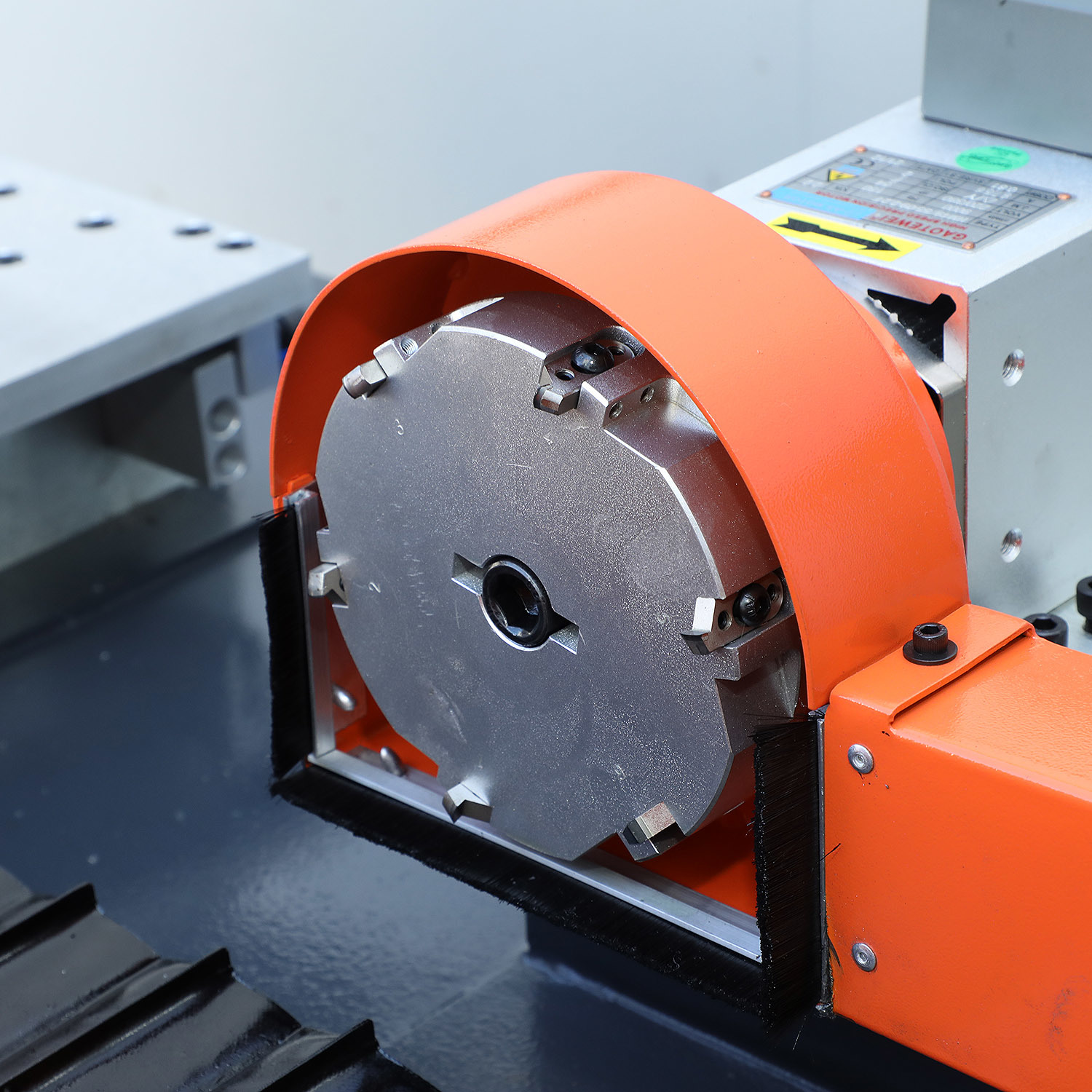

02

Spindle

7 Jan 2019

Spindle motor:2.2KW

Spindle speed:9000RPM

Cooling:air cooling

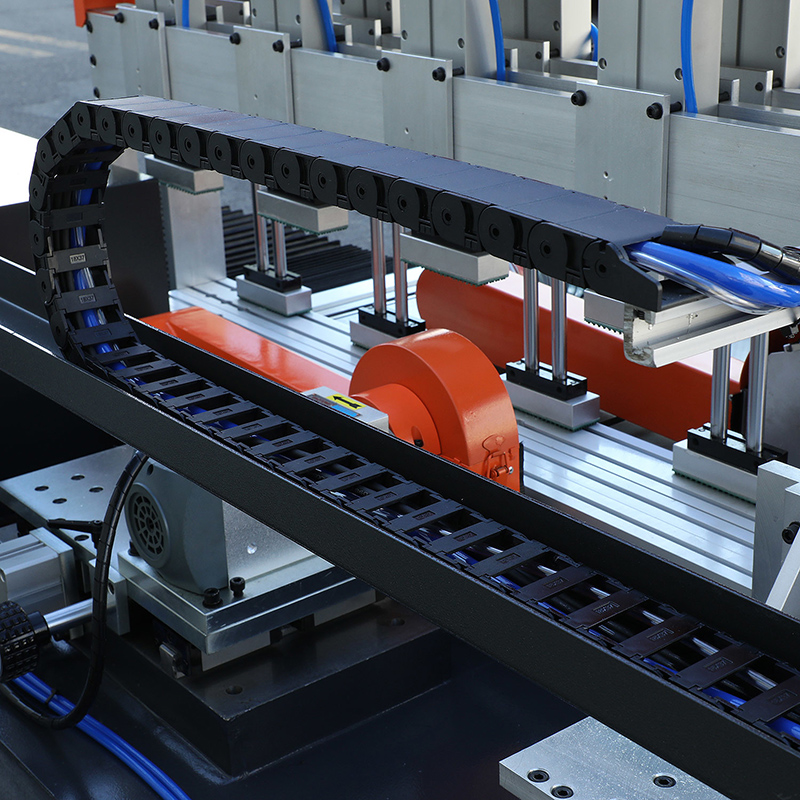

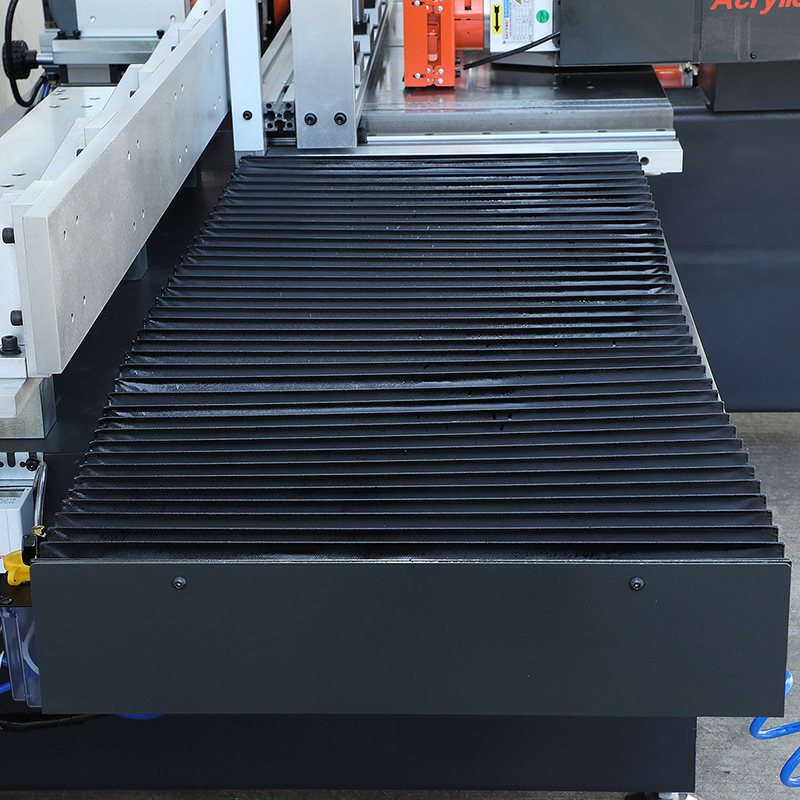

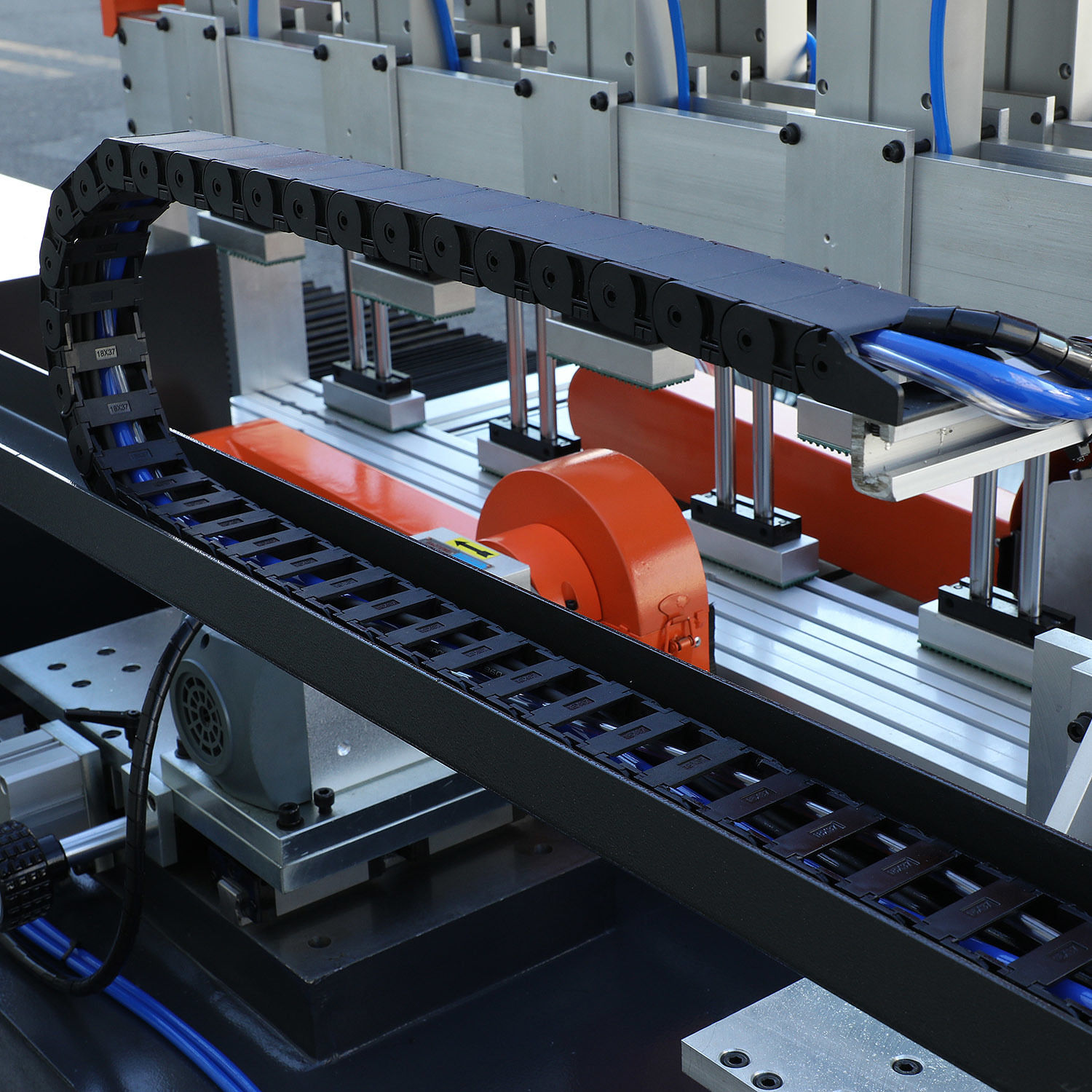

03

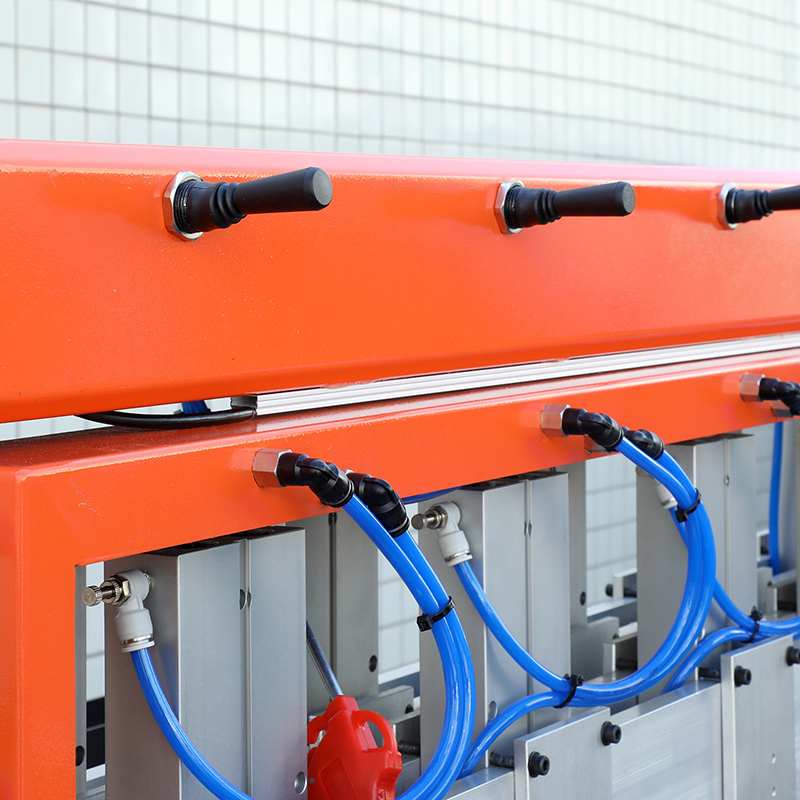

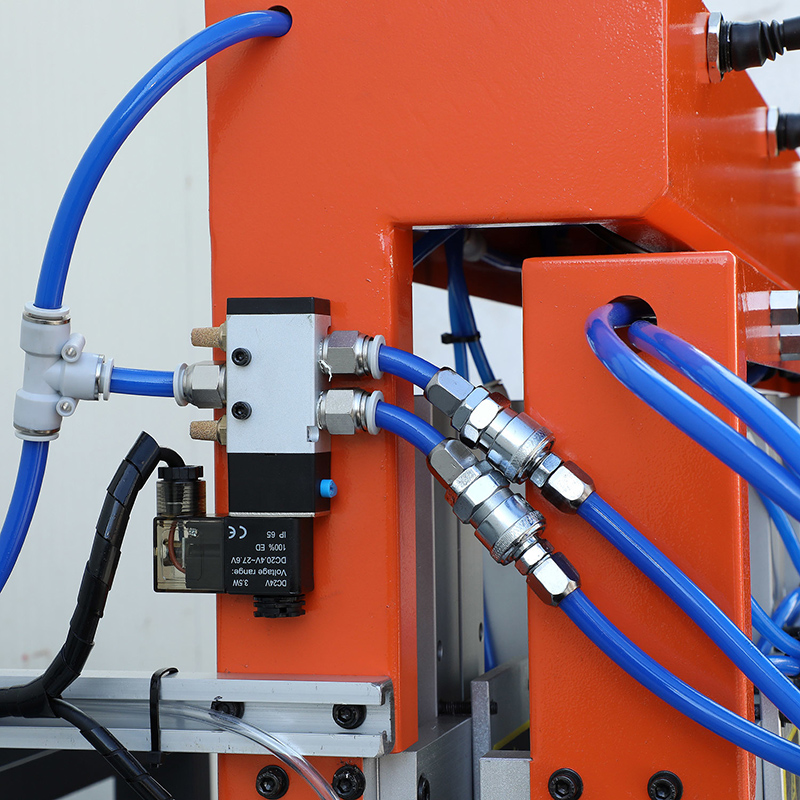

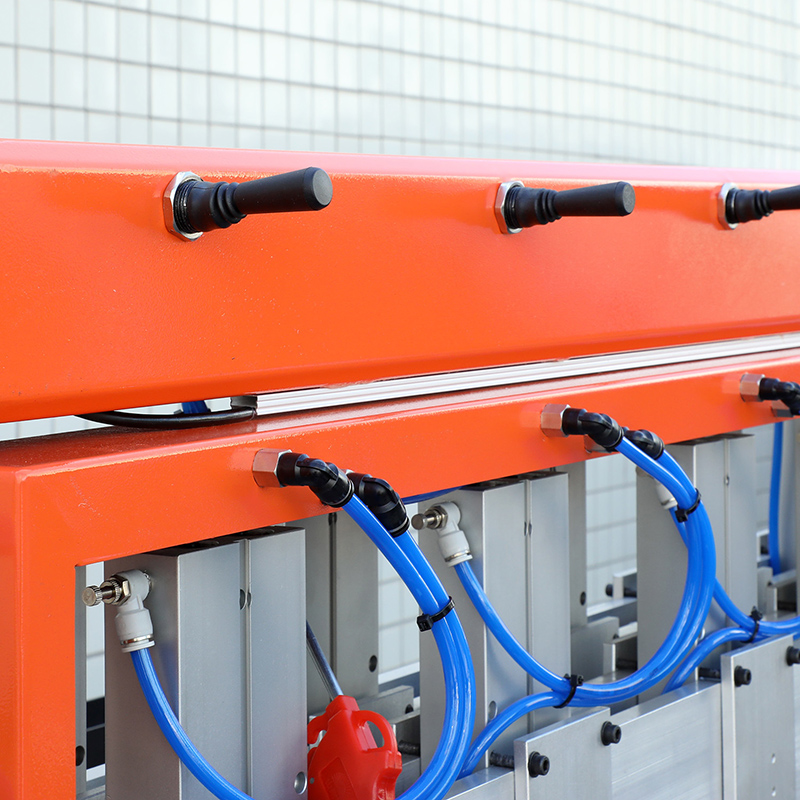

Work table & pressing mechanism

7 Jan 2019

Cast iron component slide plate.

Double row pressing mechanism, which can be disassembled when throwing small materials.

04

Tool disc & change

7 Jan 2019

Three-blade cutter head (six-blade optional).

Special tool loading device for self-loading knife, convenient and fast.

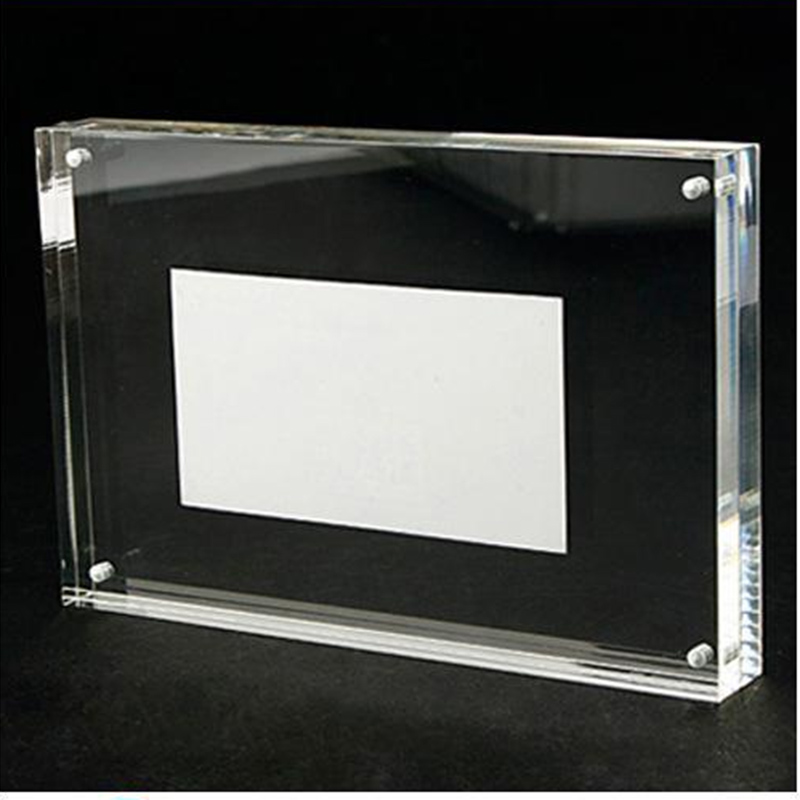

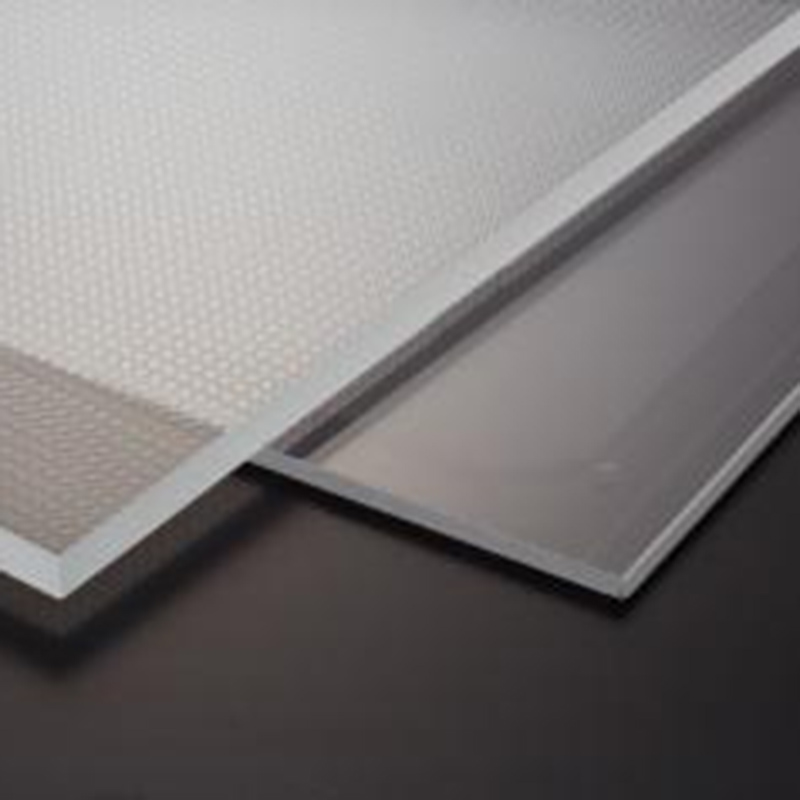

Constructed with cast iron components for its slide board, it promises stable and reliable structural integrity. Moreover, the machine comes with a dual-row compression mechanism, which is flexibly detachable to accommodate polishing of small pieces. Operators can choose between three or six-blade disc options, with a specialized tool mounting device for convenience and speed. This machine is adept at edge-polishing materials like acrylic and is suitable for use in industries such as advertising, exhibitions, home furnishings, LED lighting, light guide plate processing, and craft gifts. It is also capable of processing various materials including PC, MS, and PS. Our two decades as a manufacturer at the source mean we offer abundant experience and advantages, including a steady supply of products and reliable after-sales service. We also provide customized services tailored to customer needs, complete with comprehensive technical support and solutions. Opting for our acrylic double-sided diamond polisher ensures an efficient, precise solution for your processing needs.