Mintech Safe Benchtop R6S CNC Router

-

Spindle motor:7.5KW Automatic tool change.

-

Spindle speed:4000—24000RPM

-

Splint specification:ER25

-

Cooling: water- coolant.

Machine Specification

|

Model |

R6S |

|

Working voltage |

AC380V / 220V /50HZ / 3PH |

|

Working size |

1250mm * 2500mm * 60mm |

|

The height from beam to working table |

150mm |

|

Z axis travel |

100mm |

|

Max working speed |

10m/min (Tools required for maximum cutting) |

|

Maximum idle speed |

15m/min |

|

Repeated positioning accuracy |

+ / - 0.05mm |

|

Driving mode |

X, Y axis adopt bevel gear rack transmission; The Z axis adopts the high precision ball screw drive. |

A List Of Machine Configurations

|

NO |

Desc. |

|

Parameter |

Remarks |

|

1 |

Working area |

X axial processing scope |

1250mm |

|

|

Y axial processing scope |

2500mm |

|

||

|

Z axial processing scope |

100mm |

|

||

|

2 |

Machine parameter index |

X,Y,Z axial motion positioning accuracy |

0.05mm |

|

|

X,Y,Z repeated positioning accuracy |

0.05mm |

|||

|

Maximum displacement speed |

15m/min |

|||

|

Maximum processing speed |

10m/min |

|||

|

total weight of machine tools |

About 1500KG |

|||

|

machine tool operating voltage |

AC380V//50HZ/3PH |

|||

|

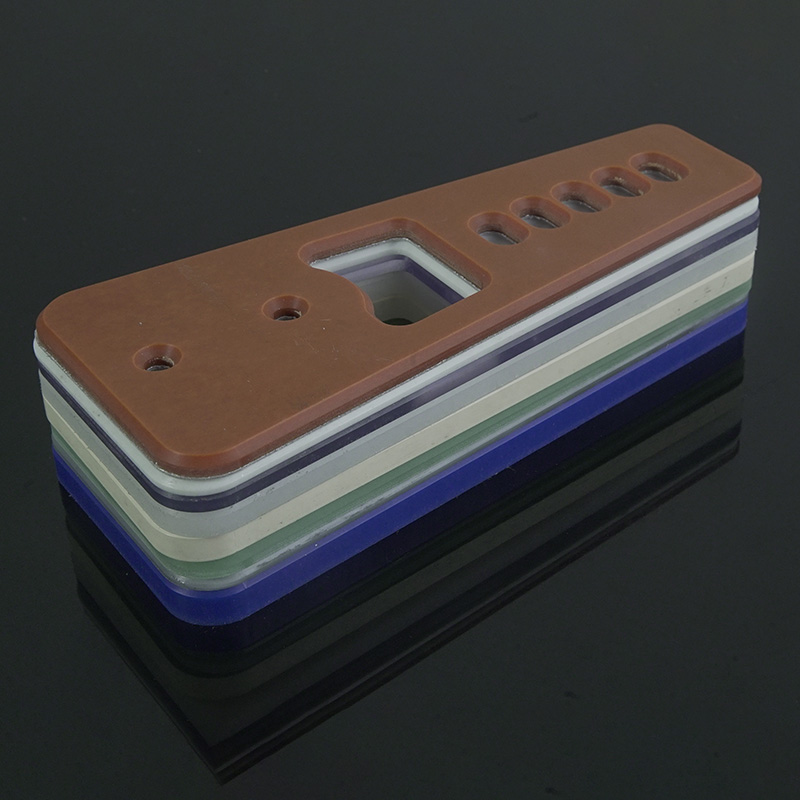

3 |

Working table |

phenolic panel table |

vacuum adsorption table |

|

|

worktable load |

200KG |

|

||

|

4 |

Software |

Handle control |

Handle control |

|

|

5 |

Tool changer- ATC |

Automatic tool change |

|

|

|

6 |

Drive power(INVT Servo motor ) |

X axial drive motor |

INVT servo drive |

Delta option |

|

Y axial drive motor |

INVT servo drive |

Delta option |

||

|

Z axial drive motor |

INVT servo drive |

Delta option |

||

|

|

|

|

||

|

7 |

Electric spindle(frequency conversion) |

spindle |

water cooling |

|

|

spindle speed |

24000RPM |

|

||

|

spindle power |

7.5KW |

|

||

|

8 |

Guide rail |

X axle guide rail |

square guide rail |

|

|

Y axle guide rail |

square guide rail |

|

||

|

Z axle guide rail |

square guide rail |

|

||

|

9 |

Drive

|

X shaft drive |

bevel teeth |

|

|

Y shaft drive |

bevel teeth |

|

||

|

Z shaft drive |

ball screw |

|

||

|

10 |

Vacuum pump |

5.5KW air pump |

one |

|

|

11 |

Kui tsui |

ER25(Ø3.175,Ø4,Ø6) |

Each one |

|

|

12 |

Single-edged tool |

ER25(Ø3.175,Ø4,Ø6) |

Each one |