01

Mintech T6 CNC Cutting Router

-

Working voltage:AC380V /OR 220V /50-60HZ / 3PHWorking size:1250mm * 2500mm * 100mmThe height from beam to working table:130mm

| Model | T6 | |

| Working voltage | AC380V /OR 220V /50-60HZ / 3PH Working size | 1250mm * 2500mm * 100mm |

| The height from beam to working table | 250mm | 250mm |

| Max working speed | 20m/min (Tools required for maximum cutting) |

30m/min Maximum idle speed |

| Repeated positioning accuracy | ±0.05mm(within 300mm) | |

| Driving mode | X, Y axis adopt bevel gear rack transmission,the Z axis adopts the high precision ball screw drive. |

Operation software using WeiHong control system .

Tool compensation function.support tool radius compensation and length compensation measured by both manual and automatic modes,easy to understand human-computer interface,make users reduce the conversion of tool compensation values for users using tool length compensation,avoidance of many unnecessary conversions.

Program simulation and real-time simulation provides powerful program simulation capabilities,can fully display the process of rough cutting.The program simulation function also supports the transition between the analog interface and the processing interface at any time.It is convenient for users to monitor the processing program in real time to make the processing convenient.

Complete precision machining of milling drilling angle and other functions in one clip.Adopt high precision ball screw guide gear bar to ensure machine stability.

Spindle motor:9 KW Automatic tool change .4000—24000rpm ER32 ISO30 air- cooling

Straight-line tool changing system (5 Tools position)

| NO | Desc. | Parameter | Remarks | |

| 1 | Working area | X axial processing scope | 1250mm | |

| Y axial processing scope | 2500mm | |||

| Z axial processing scope | 100mm | |||

| 2 | Machine parameter index | X 、 Y 、 Z axial motion positioning accuracy | 0.05mm/300mm | |

| X 、 Y 、 Z repeated positioning accuracy | 0.05mm/300mm | |||

| Maximum displacement speed | 30m/min | |||

| Maximum processing speed | 20m/min | |||

| total weight of machine tools | About 2500KG | |||

| machine tool operating voltage | AC380V/OR 220V/50-60HZ/3PH | |||

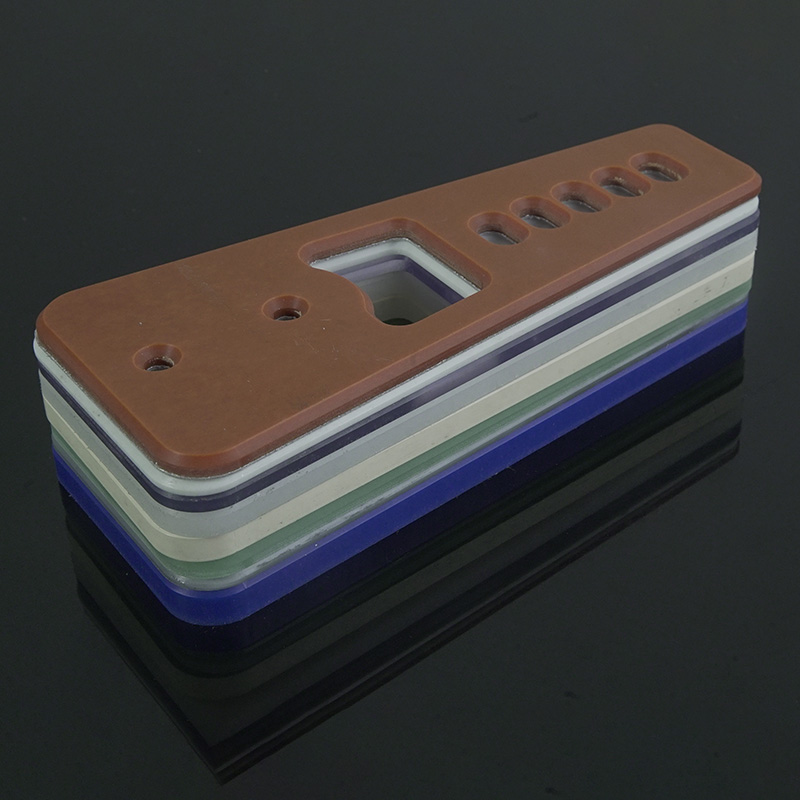

| 3 | Working table | phenolic panel table | vacuum adsorption table | |

| worktable load | 380KG | |||

| 4 | CNC System | Wei Hong | NK 280 | |

| 5 | ATC | Staight-line tool changing system | 5pcs in one row | |

| 6 | Drive power ( SERVO MOTOR ) | X axial drive motor | Delta | Taiwan |

| Y axial drive motor | Delta | Taiwan | ||

| Z axial drive motor | Delta | Taiwan | ||

| 7 | Spindle | Spindle Cooling | Air cooling ATC | |

| Spindle speed | 24000RPM | |||

| spindle power | 9 KW | |||

| 8 | Guide rail | X axle guide rail | square guide rail (25mm) | |

| Y axle guide rail | square guide rail (25mm) | |||

| Z axle guide rail | square guide rail (20mm) | |||

| 9 | Drive | X shaft drive | Helical rack | |

| Y shaft drive | Helical rack | |||

| Z shaft drive | ball screw | |||

| 10 | Vacuum pump | High pressure air pump | 5.5KW |