Mintech Ball Screw Laser Machine MC-2500

-

Working area:W:1250mm,L:2500mm

-

Laser tube:150w/300w/450w/600w

-

Cutting head:Quick install, precision adjust

Screw-Driven High-Precision Cutting Machine

Mc-2500 Detailed Configuration

|

Item |

Specification |

Remark |

|

Working area |

W:1250mm,L:2500mm |

Machine annealing and precision machining |

|

Laser tube |

150w/300w/45ow/600w |

Optional |

|

Cutting head |

Quick install, precision adjust |

Mintech |

|

fixed beam |

beam compensation |

Mintech |

|

Polarizer system |

X/Y same cutting gap |

Mintech |

|

Mirror |

High reflecting(>99.5%) |

from USA |

|

Machine driven system |

X/Y axis ball screw |

Import from taiwan |

|

X/Y/Z TBI/PMI linear guide |

Import from Taiwan |

|

|

Special cooling system |

Precision: ±0.5℃, protection: compressor protection;water flow; high temp、low temp |

S&A/TongFei |

|

Control system |

Off line control |

Ruida |

|

Servo motor |

MITSUBISHI |

Import from Japan |

|

Software |

Ruida |

|

|

Section exhaust |

two section |

Mintech |

|

Main contactor |

LS |

Import from Korea |

|

Main solenoid valve |

SMC |

Import from Japan |

|

Origin switch |

Optoelectronic |

Import chip |

|

Machine cable |

High flexible cable |

Yichu |

|

Water cooling mirror |

Stable working guarantee |

Mintech |

|

Lens |

|

It is made from Bejing |

Technical specification

|

PARAMETER |

MC-2500-300W |

|

|

Laser output power (W) |

300 |

|

|

M2- Transverse mode quality |

M2≤1.1 |

|

|

Worktable dimension(mm) |

1250×2500 |

|

|

Worktable load (kg) |

300 |

|

|

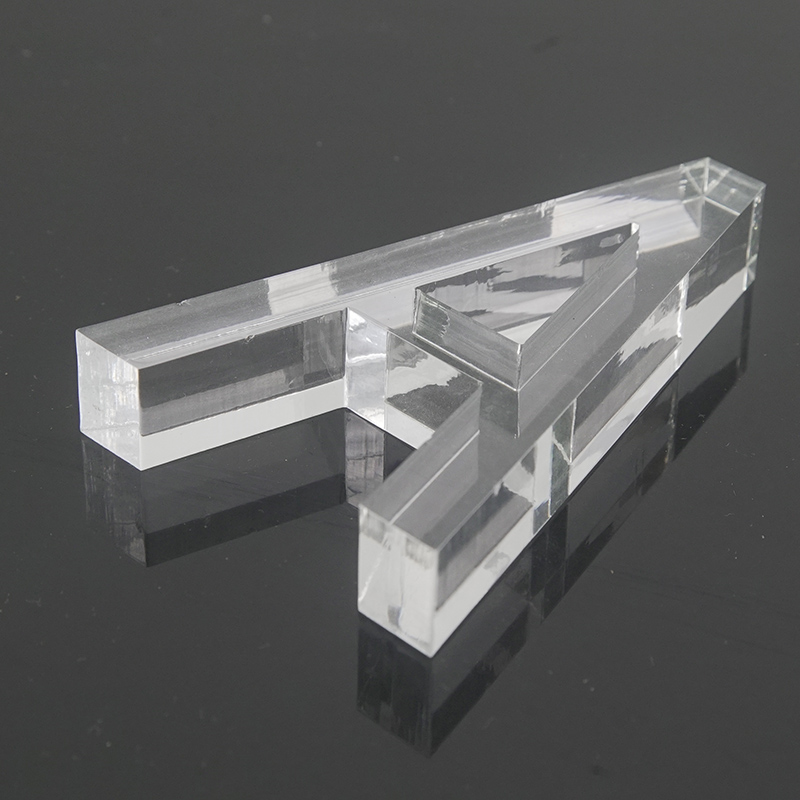

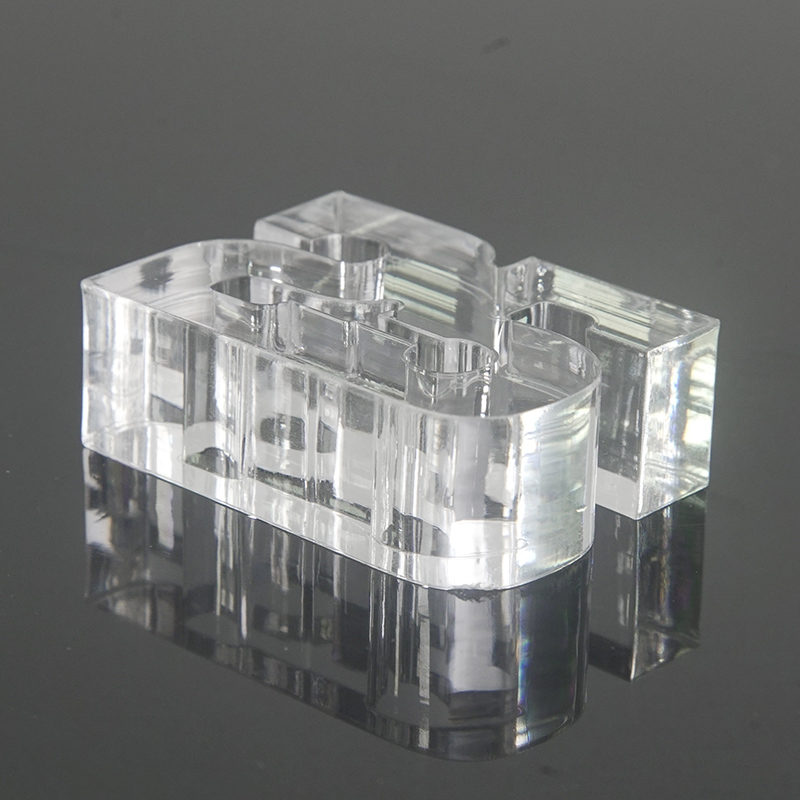

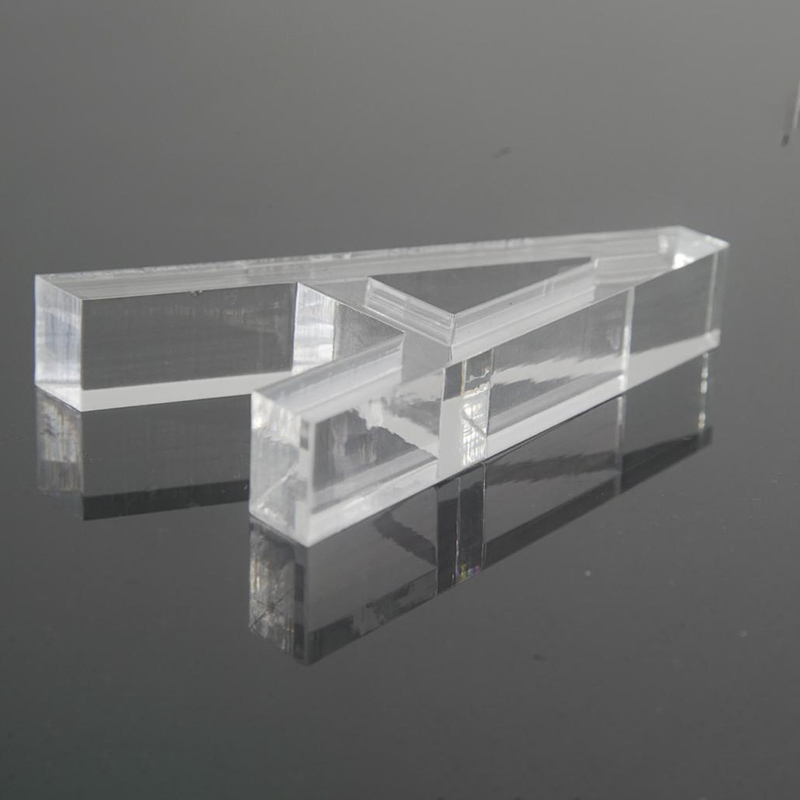

Acrylic cutting ability(mm) |

30 |

|

|

Dieboard cutting ability(mm) |

12 |

|

|

Speed of positioning (m/min) |

20 |

|

|

Positioning accuracy(mm/m) |

±0.05 |

|

|

Repeatability accuracy(mm) |

±0.05 |

|

|

Travel |

X-axis(mm) |

1250 |

|

Y-axis(mm) |

2500 |

|

|

Z-axis(mm) |

60 |

|

|

Power supply(50/60Hz) |

Single-phase 220V |

|

|

Full current(A) |

30 |

|

|

Pressure of accessorial gas (MPa) |

0.6 |

|

|

Dimensions(L×W×H) (mm) |

3600×1900×1200 |

|

|

Machine net weight (kg) |

1500 |

|

|

Room dimensions(L×W)(mm) |

5000×2800 |

|

Environment Requirement

|

Item |

Description |

Remark |

|||

|

Machine floor Space |

5000mm×2800mm |

|

|||

|

Power request |

1 phases 220VAC±10%/30A |

|

|||

|

Chiller temperature |

15-30℃ |

Adjust according to the environment temperature and humidity |

|||

|

Environment temperature |

15-28℃ |

Operational temperature |

|||

|

Store temperature |

>5℃ |

|

|||

|

Relative humidity |

<60% |

|

|||

|

Floor requirement |

Slab floor should brushed lacquer |

Keep source |

away |

from |

Shaking |

|

Workshop environment |

Clean and dustless |

|

|||

|

Computer |

P4/256M/WIN2000 or above version |

Minimum requirement |

|||

|

Air compressor |

Capacity, 0.7m3; pressure, 7kg/cm3 (100psi) |

The dimension of the interface is φ8mm |

|||

|

Demineralized water or distilled water |

20L |

Should be changed every 3 or 4 months |

|||