01

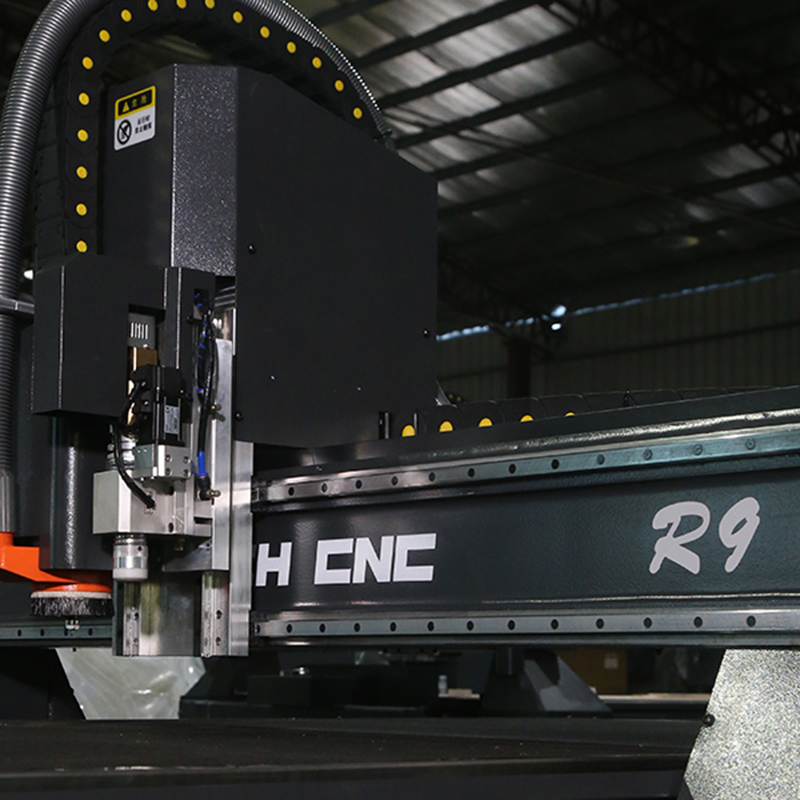

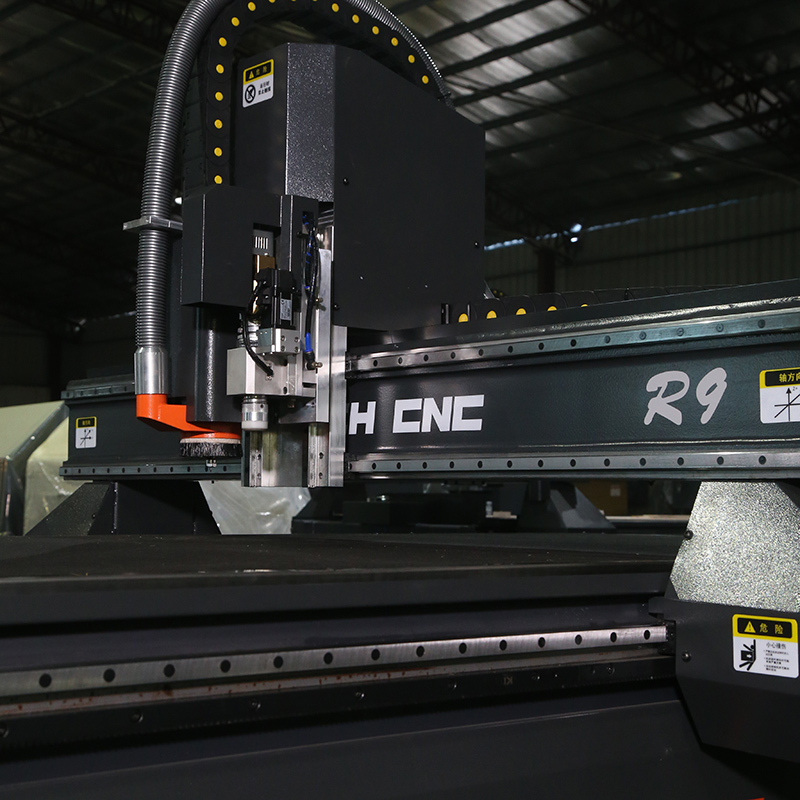

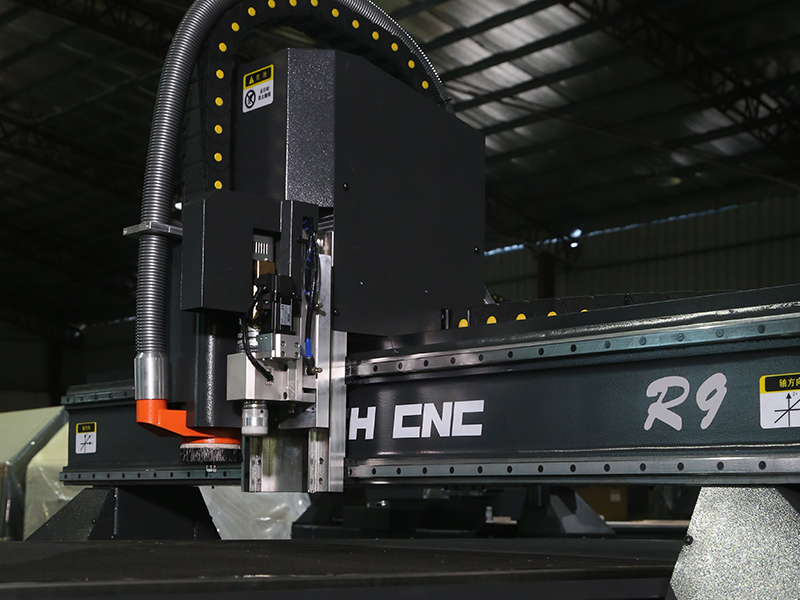

The Entry-Level R-Series Engraving Machine MINTECH CNC Router

-

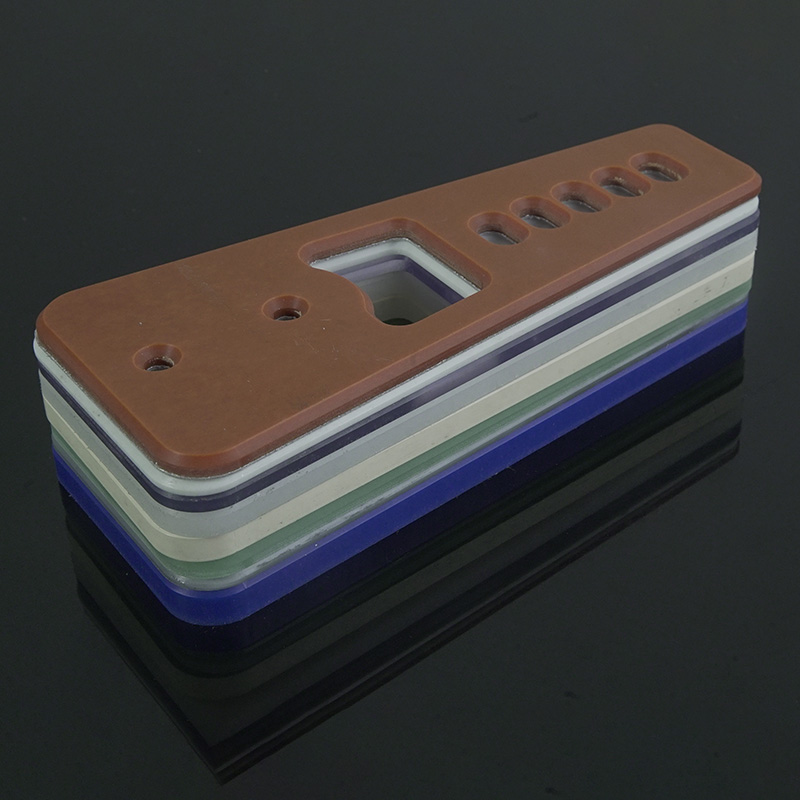

The Oscillating knife can be used for cutting leather、PU、PVC、KT board、corrugated paper.

Machine Specification

|

Working voltage |

AC380V / 50HZ / 3PH |

|

Machinable size |

1300mm * 2500mm * 60mm |

|

distance from beam to table surface |

150mm |

|

Z-axis stroke |

160mm |

|

Maximum processing speed |

30m/min (tool coordination is required for maximum cutting) |

|

Maximum idle movement Speed |

60m/min |

|

Repeatable positioning accuracy |

+/-0.05mm |

|

Drive mode |

X and Y axis are driven by high-precision helical gear rack, and Z-axis is driven by high-precision ball screw. |

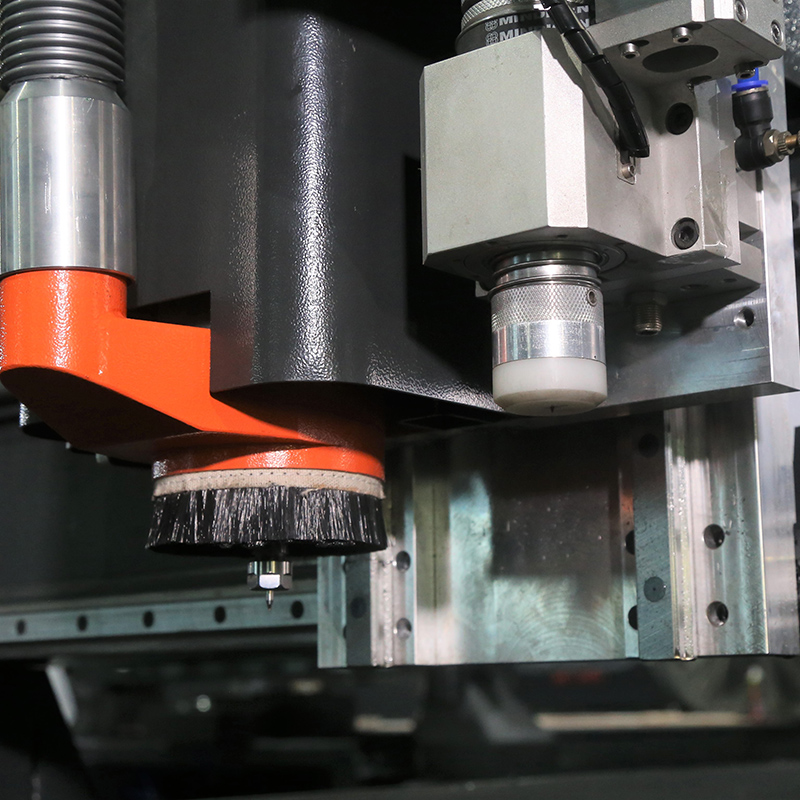

The machine is centered around a potent high-speed spindle, providing a substantial 1.6KW of power coupled with an extraordinary operational speed of up to 60,000rpm. This precision-engineered, water-cooled spindle has been meticulously crafted to ensure a seamless and efficient cutting process, enhanced by a convenient manual tool change mechanism. Its superior cutting performance is optimized for a diverse array of materials, offering versatility and reliability for various professional needs.

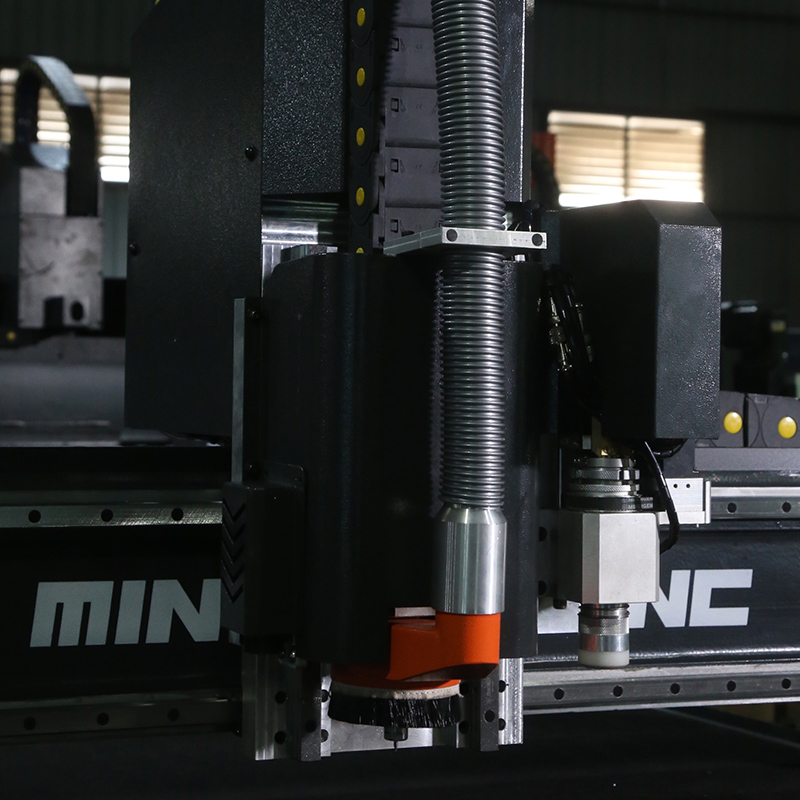

Furthermore, the inclusion of an oscillating knife system marks a significant advancement in cutting technology. Operated by a servo motor designed for high-speed tasks, the knife moves with exceptional precision, making swift and accurate cuts a standard output. The system’s flexibility allows for an easy interchange of knives, making it suitable for cutting a range of materials including leather, PU, PVC, Oxford fabric, corrugated paper, and KT board.

This high-speed cutting machine is the ideal solution for industries with multifaceted cutting demands. It stands as a pivotal tool for businesses specializing in advertising, textile processing, and the creation of crafts and composite materials. Its ability to handle delicate and thin materials with meticulous precision gives it a significant edge over traditional cutting methods.

Enhance the efficiency and quality of your cutting tasks with MINTECH's custom CNC system. This system streamlines your operations, enabling smooth transitions between spindle cutting and oscillating knife cutting without sacrificing speed or accuracy.

In summary, MINTECH's high-speed cutting machine is a transformative addition to any production environment, combining state-of-the-art features with straightforward operation. With its advanced capabilities and exceptional precision, it represents a leap forward in cutting technology, ready to elevate your company's material processing to the next level.

Machine Configuration List

| NO | content | specification | Remarks | |

| 1 | Processing range | X axis processing range | 1300mm | |

| Y axis processing range | 2500mm | |||

| Z axis processing range | 60mm | |||

| 2 | Machine parameter index | |||

| X, Y, Z axis motion positioning accuracy | 0.05mm/300mm | |||

| X, Y, Z repeat positioning accuracy | 0.05mm | |||

| Maximum displacement speed | 60m/min | |||

| Maximum processing speed | 30m/min | |||

| Total machine weight | About 1500KG | |||

| Machine working voltage | AC380V/50HZ/3PH | |||

| 3 | Workbench | Phenolic Panel Workbench | Four-zone vacuum adsorption table | |

| Workbench load | 300KG | |||

| 4 | CNC system | Mintech professional CNC system | handle | |

| 5 | Tool change system | Manual | ||

| 6 | motor | X axis drive motor | Servo drive | Resay |

| Y axis drive motor | Servo drive | Resay | ||

| Z axis drive motor | Servo drive | Resay | ||

| 7 | Electric spindle (frequency conversion) | Spindle | Water cooling | |

| Spindle speed | 60000RPM | |||

| Spindle power | 1.6KW | |||

| Spindle taper | Ø3-Ø6 | |||

| Spindle dynamic balance level | G2.5 | |||

| Frequency converter | Ivnt | |||

| 8 | guide | X rail | Square rail (20mm) | TBI |

| Y axis guide | Square rail (25mm) | TBI | ||

| Z axis guide | Square rail (20mm) | TBI | ||

| 9 | transmission | X axis transmission | Helical rack + reducer | |

| Y axis transmission | Helical rack + reducer | |||

| Z axis transmission | Ball screw rod | TBI | ||

| 10 | Oscillating knife | Invt motor18000RPM | Tool and taper can be changed |